Shared Passion

We believe that a company’s culture is the key to its success.

At Yangrima Tibetan Rugs company, our hand-knotted rugs are the result of shared passion and dedication of many artisans involved in the process.

With the mission of producing and providing customers with the best possible quality rugs, we have also been able to change lives here at our home by providing employment to the locals. With each rug you buy from us, you also help a family grow here in Nepal.

Why buy from us?

- – hand knotted with ancient Tibetan craft

- – amazing factory prices in all rugs

- – free samples before your purchase

- – free shipping and handling

- – child labor free

- – have your custom designed rug

Member of:

—-

Our Rug Making Process

A rug-making involves various thorough process before it is laid on our floor. It is important to ensure each one of them is done carefully and precisely.

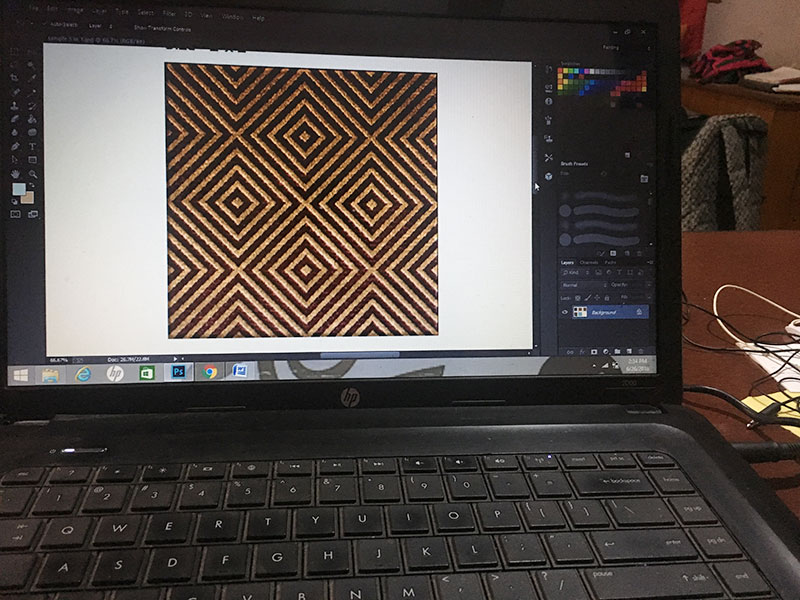

- Designing and Graphing

- Choosing the yarns

- Dyeing

- Color Sampling

- Weaving

- Washing

- Stretching

- Trimming

- Inspection

Responsible Weaving

View more

The integral part

View more1. Designing and Graphing

The first step in the rug making process entails designing and graphing of the rug. It also happens to be the integral part in the process as we can see what the rug will look like after it is finished.

2. Choosing the yarns, Dyeing and color sampling

After the graph is ready, the yarn is carefully chosen and dyed as per order. Then the threads are sampled together for the weaver to use it as a reference for the yarn number in the graph and weave

The careful part

View more

The skill part

View more3. Weaving

The rug is then given to weave to a skilled weaver. After the rug is done weaving, it is taken off the loom and brought at the plot to wash.

4. Washing

The rug is washed thoroughly after it is trimmed with eco friendly chemicals to bring out the best texture and sheen. It is then dried on the sun and turned frequently to ensure complete dryness.

The best texture

View more5. Stretching

The rug is then stretched to bring it in its proposed size. It is done as the rug usually shrinks in size during the wash. However, the size of the rug may vary from the actual size as the entire rug making process is done by hand

Final trimming and inspection

The rug is then hand trimmed carefully either with the help of a pair of special scissors or a machine (depends on the type of rug). It is done to remove the unnecessary strands of threads and to reveal the sheen and texture. A final inspection is done to ensure the rug’s condition at all sides and then shipped to its destination.